Asmote has various industry leading gas sensors to satisfy wide range of gas detection needs, including pure gas as well as gas mixture which has multiple components. High accuracy sensors guarantee real-time and high quality data to keep situation under control for chemical and oil gas plants which requires extremely high standard for environment safety.

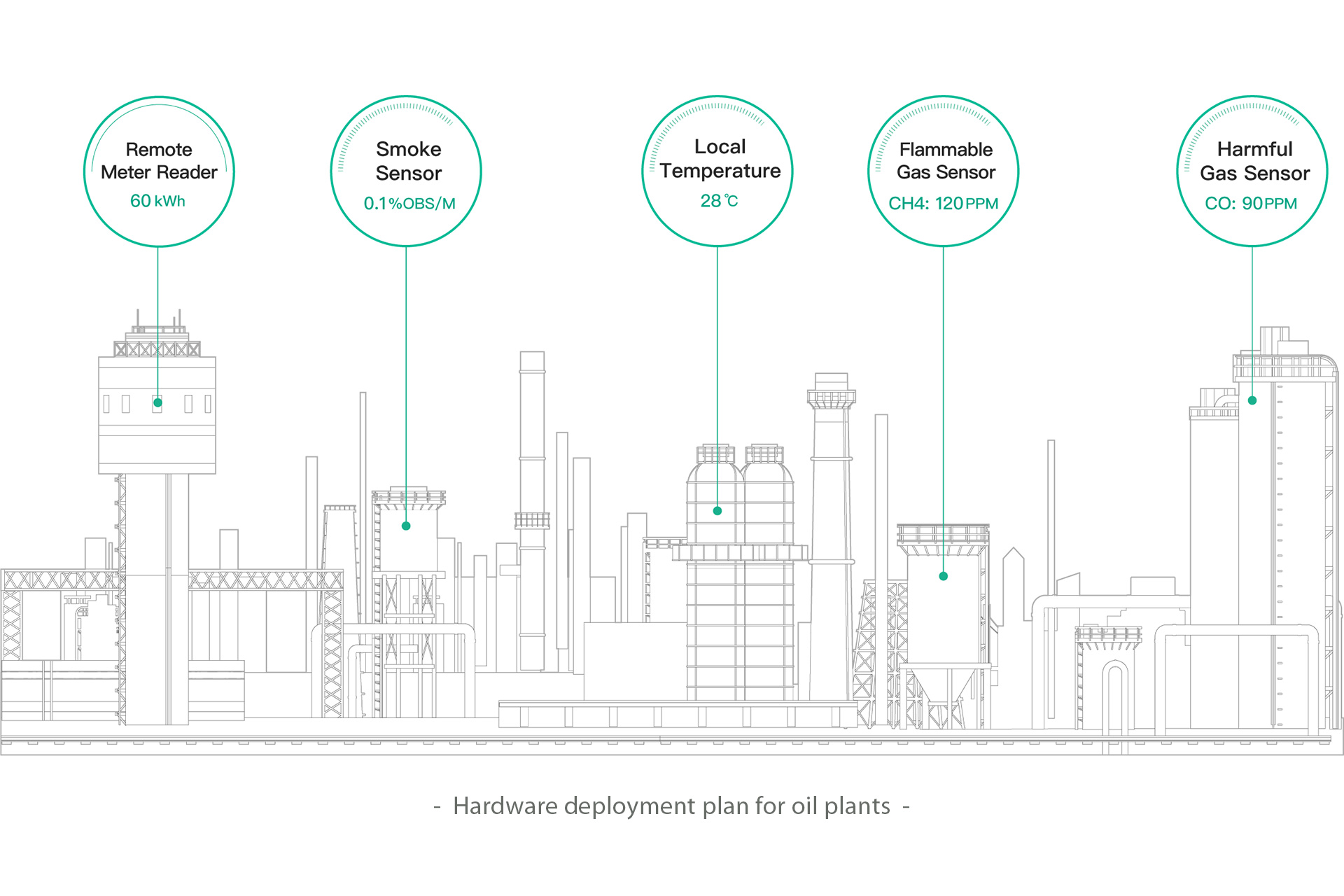

Remote Meter Reader

Reads meter readings remotely. Since gas plants consume large quantity of resources like fuels, water, automatically and remotely records all meter readings could save significant cost of sending staff to take readings from meters all around the plant.

Smoke Sensor

Senses smoke in case of fire or burning, which are extremely dangerous for oil plant environment. Alert the nearest fire unit to dispose of the situation.

Temperature Sensor

Detects temperature across the plant as well as some specific critical places or surfaces, with probe or infrared, to watch closely for any abnormal temperature fluctuation that may lead to danger.

VOCs, Toxic and Flammable Gas Sensor

Oil plants produce various kinds of VOCs, toxic and flammable gas during production process and any of them could cause serious consequence. Asmote’s various gas sensors detects concentration of specific gas or gas mixture in sensitive and critical locations to identify and potential hazard at very early stage.

Summary

With Asmote high accuracy sensor network for manufacturing environment, critical information about environment (concentration of toxic gas, temperature, etc) can be watched real-time with high accuracy. The high-standard and reliable monitor system guarantees safety with low cost as well as construction flexibility compared with tradition monitor system.